Rigid membrane surfaces made to emit sound by exciters – what sounds like every interior designer’s dream often turns out to be more compromise than concept. Many approaches struggle to compensate for their weaknesses with brute force and excessive technology. Piano builder Michael Symann demonstrates that there is a much simpler – and, above all, far better – way, if you truly understand music and master your craft.

The idea of surface excitation is, of course, not new. Almost whenever manufacturers talk about “invisible speakers” or “sounding walls,” they are referring to large panels set into vibration by exciters. More often than not, these concepts are based on acoustically questionable materials such as drywall or plywood. Because of the damping properties of such membranes, pleasing musical reproduction can usually only be achieved through the use of powerful Class-D amplifiers and corrective DSPs. In addition to the already nontrivial installation, you end up with electronics that only experts can operate. This hardly feels like a solution ready for the mass market.

Scene 1: Everything Was There All Along

And then there are moments when exactly the right people cross paths. In 2017, a customer approached Michael Symann about surface excitation. As an expert in instrument woods, might he have an idea how to get an exciter-driven loudspeaker under control? The master piano builder, based in Verl in eastern Westphalia and an indefatigable tinkerer, began to ponder the question and started experimenting with different types of wood and material thicknesses in his workshop. Before long, he came to the realization that the whole thing could be implemented entirely in the analog domain and that no power superlatives were needed for excitation – after all, that’s exactly what he does all day long with his pianos.

I listen to the passionate craftsman’s explanations in an unusual setting. Instead of a listening room, we’re sitting comfortably at a dining table in the Symann family’s living room. Aside from a large corner sofa with a side table, a television, and a custom-built hi-fi rack, the room is sparsely furnished. A “modern” living space – not exactly easy terrain for a speaker demonstration. Against the narrow wall opposite a glass front opening onto the terrace stands a piano, Michael Symann’s masterpiece, as I learn, which he has cherished and maintained for decades. To its left and right rise human-height monuments made entirely of wood, which at this very moment envelop us in warm piano tones, string textures, and endlessly deep reverberation tails.

Michael Symann didn’t execute his DBS-170 as an in-wall solution, but as a flat loudspeaker that is comparatively easy to integrate. There is no optimal listening position in the classical sense – after all, when listening to a pianist, you don’t first look for the perfect spot; you simply listen and enjoy. “We often sit on the sofa, read, and let the music play in the background,” explains the creator of the two sound walls. They were designed to flood a room harmoniously with sound – and that is exactly what they do: expansive, clear, and omnipresent. As I stand up and try different positions, I’m amazed at how homogeneously the soundscape generated by the DBS-170 illuminates the living space. Whether from the sofa, near the glass front facing the garden, or in a corner of the room – the music sparkles with excellent timing and wonderfully natural colors.

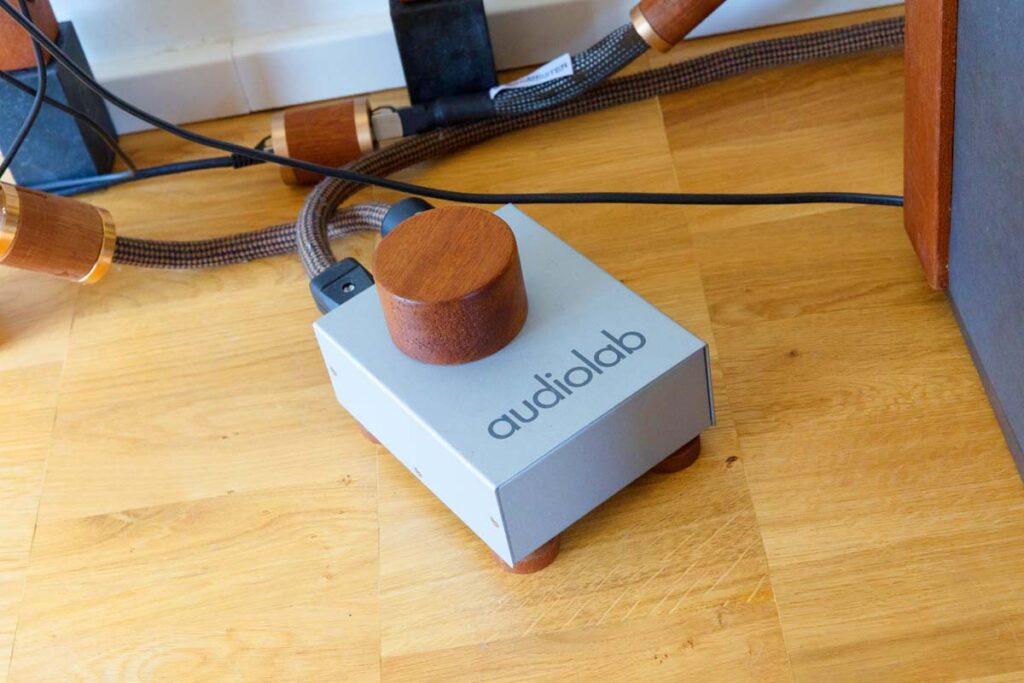

And before you ask: there is no active electronics involved – at least not in the speakers themselves. Michael Symann selects music from a Qobuz playlist managed with Audirvana on a laptop. Streaming and conversion are handled by a Marantz ND 8006, while amplification is provided by a modified 30-watt tube amplifier. Unassuming, if you will. Long speaker cables run through the walls and feed banana terminals in the massive base of the DBS-170. The base alone weighs 35 kilograms and provides the necessary stability for the sound panels, which themselves weigh just under 20 kilograms each.

The soundboards do not require crossovers, Michael Symann explains. Instead, he uses a technique borrowed from piano building: the multi-part panels he glues together for the front and rear of his speakers are relatively thick at the top and taper toward the bottom. The frequencies travel through the wood and naturally find their preferred wall thicknesses. Bass frequencies, for example, like thin, soft layers that yield to them and allow a certain amount of excursion. High frequencies, on the other hand, demand hard surfaces and therefore favor the more stable areas of the panel. Each of the four gently curved, internally braced soundboards houses three exciters. The DBS-170 are identically constructed on both sides and radiate in phase to the front and rear. The exciter positions are easy to spot, as they are anchored in the wood with metal pins visible as silvery rings. Relatively high up, only on the front side, an air-motion transformer is installed to complete reproduction in the manner of a super tweeter above 12 kHz. The two soundboards of the DBS are connected at the top and bottom, as well as by two side rails glued in place and tensioned with a metal rod. This rod prevents resonances and ensures that vibrations are radiated only via the sound surfaces.

Scene 2: From Tree Trunk to DBS

When I begin asking detailed questions about the speaker construction, Michael Symann stops me. He can explain it much more easily in the workshop, where he is currently building the smaller sibling of the 170 for a customer, the DBS-136. On the way there, he first leads me into his showroom, where seven upright pianos and a grand piano await customers. In addition to customer restoration work, this is his primary profession: the master piano builder buys used pianos, refurbishes them, and sells them at fair prices. Immediately, he draws my attention to a black Sauter upright standing right by the entrance. Hidden here, he says, is a key foundation for the construction of the soundboards. He has expanded the piano with a mechanism that allows the keyboard to be decoupled from the hammers. Sensors in the keyboard register keystrokes and forward them to an electronic sound generator with a headphone amplifier, allowing pianists to practice late at night without disturbing the entire neighborhood. But the piano can do even more: Michael Symann installed the very same exciters behind the piano’s panel that he later used in the DBS – so he already had all the necessary parts for experimentation. He quickly sits down and demonstrates the instrument, selecting various piano, electric piano, string, and organ programs on the small tone generator. They sound crystal clear in the room and – unlike the acoustic piano – can be adjusted in level.

Shortly thereafter, we are standing in the workshop, which consists of two connected rooms. In the first, two Steinway grands await completion. One is receiving a new action on behalf of a customer – over the years, felt hammers become flattened through use, so they need to be replaced from time to time. The refurbished parts are lined up neatly on a windowsill, waiting for installation. The second grand is a long-term project of Michael Symann’s: he had always wanted to own a Steinway of his own and discovered an affordable specimen that still requires a great deal of care and attention.

In the next room, I finally see the DBS-136 – or rather, one of its soundboards. The three wooden panels that make up each wall are already glued together, and the internal ribs have been installed, giving the construction its distinctive curvature. To force them into the material, the craftsman devised a perforated ceiling element for his workshop. To demonstrate the principle, he positions a long wooden pole, aims it at one of the ribs, and – snap! – a triggered latching mechanism presses the wood downward with incredible force.

The perforated ceiling is not the only aid the piano builder has invented. Michael Symann shows me several curved metal profiles with hinges, drill holes, and levers – objects I cannot begin to make sense of. They are parts of a piano lifter and rotator he developed himself: it is mounted under a grand piano, lifts the instrument, rotates it 90 degrees along its longitudinal axis, and allows it to be rolled relatively comfortably through a doorway – all by a single person. To prove it, he installs one of the lifters under a Steinway and asks me to operate the lever. Almost frighteningly easily, the instrument glides upward under my movement – it’s all about proper leverage, I learn. Michael Symann needed this tool because his workshop is fitted with standard interior doors. He also tells me that some time ago, because he repeatedly needed screwdrivers and other tools in special sizes, he set up his own metal workshop. There he manufactures these transport aids to order. In addition to freight companies and piano builders, he has also supplied concert halls. “Hard to believe,” he adds, “but they often have doors that are too small as well.”

From there, the host leads me across the yard into a converted garage that houses his carpentry shop, a paint room, and the aforementioned metal workshop. Waiting there is another soundboard for the DBS-136, still looking quite raw. After brief preparation, Michael Symann begins routing the six glued ribs into their final shape. Only now do I realize that each rib looks slightly different and that the router must be reset after every step. The flexibility of the ribs plays a role in distributing sound across the membrane surface. Alongside long resting times for the glue to cure, it is details like these that explain why it takes him weeks to build a pair of speakers.

It should be emphasized just how remarkable the depth of in-house manufacturing is. Because Michael Symann wants complete control over every step, his work on a new soundboard begins with cutting the required planks. At the back of the carpentry shop, I spot a full log of sapeli mahogany – the dark wood strip in the center of the sound surfaces. This wood is also used for the side walls and the top. The lighter material is spruce. Since each speaker is built to order, Michael Symann can accommodate requests regarding visual design – within limits, of course, as he is bound to the woods commonly used in instrument building. Custom finishes, however, are not a problem.

Scene 3: Ambience and Space

We return once more to the living space, where I gather a few more impressions of the DBS-170. Michael Symann is a lover of handmade live music. He plays me a series of jazzy recordings, preferably atmospheric sessions from small, smoky clubs, which unfold an incredible mood through the soundboards and conjure a wonderful swing in the living room. Next come classical concert recordings, and once again I notice that the speakers shine particularly in terms of tonal color and spatial depth. Massive orchestral structures spread out across an enormous stage that is clearly larger than the room we’re in. Even though the DBS-170 operates without a subwoofer, I can feel the lower registers of double basses and timpani in my gut. The soundboard neither appears to make impressive excursions nor shows any obvious movement, yet with its several square meters of membrane area it injects tremendous energy into the room. Curious, I approach the speakers and place the back of my hand on the playing surface, which immediately begins to dance. Far more is happening than the naked eye can perceive.

Finally, vocal recordings reveal an effect inherent in the nature of such large membranes. Voices appear just as colorful and nuanced in the room as instruments, but due to the huge radiating area they sound more diffuse than through a monitor speaker. Anyone who has ever tried to find the narrow sweet spot between two electrostats knows exactly what I mean – it’s a matter of principle and getting used to it. That said, one should bear in mind that Michael Symann operates his soundboards close to the wall due to spatial constraints and with very little toe-in. Depending on room characteristics and placement, there is certainly room for further tweaking – if that’s what you want. Because above all, openness and an incredible sense of scale, which remains intact even at very low listening levels, contribute significantly to the utterly unique character of the DBS-170.

Symann Soundboards DBS-170

Concept: Surface radiator with exciter drive and AMT tweeter | Drivers: 6 × 4 cm exciters (full range), 1 × 3.6 cm AMT (super tweeter) per speaker | Connections: Single-wire banana terminals | Cabinet materials: Spruce, sapeli mahogany | Weight: Speaker 19.8 kg, base 35 kg | Finishes: Natural wood; custom paint finishes available on request | Dimensions (W/H/D): 85 × 170 × 25 cm | Warranty period: 2 years | Price per pair: around €18,900

Michael Symann

Oststraße 46

33415 Verl, Germany

Telefon +49 5207 4772

soundboards@symann.de