We had the opportunity to visit the Revox factory in Villingen, where we had a look at the legendary brands rich history and future.

A History Lesson

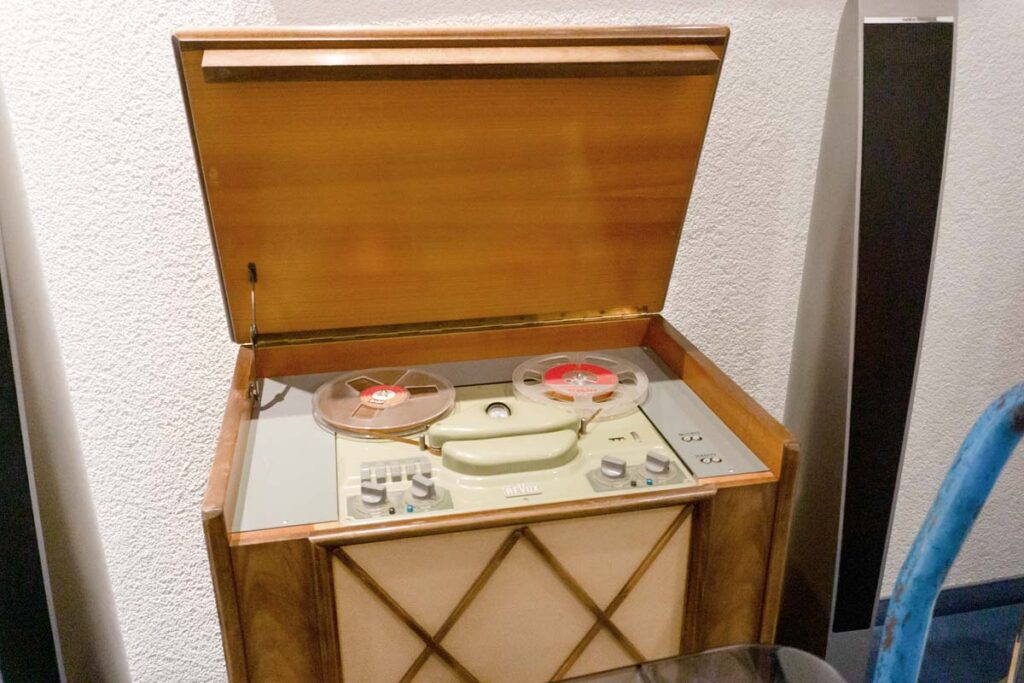

Our “Visiting Revox” documentary began with Marketing Director Jürgen Imandt giving us a tour of the company’s in-house museum, outlining the brand’s rich history. Revox was founded in 1948 by Willi Studer in Switzerland. From the very beginning, the young brand aimed to manufacture reel-to-reel tape recorders of the highest quality. As early as 1951, Studer released the T26, his first original design – a machine so well-engineered it quickly became a staple in radio broadcasting.

With the introduction of the 36 series, Revox set new benchmarks: three motors and a minimalistic mechanical design became the foundation for all future models.

After an impressive 80,000 units produced, the A77 took over in 1967 – a recorder that’s still considered one of the best in its class. The first “77 model” became one of the best-selling tape machines of its time, impressing users with its outstanding sound quality, reliability, and design. Its success laid the foundation for what many call the golden age of Revox tape recorders. Building on this legacy, the B77 was introduced in the late 1970s as an evolution of the A77, rounding off the series for the time being.

Revox and Multiroom Audio

When Revox ceased tape recorder production in the mid-1980s, it marked the start of a new chapter – in an entirely different field. In 1983, the brand launched one of the world’s first multiroom systems, long before most people had even considered the idea. Revox has continued developing the concept over the decades and has become a leading provider in the industry.

A key innovation is the system’s “multi-user” design: each family member can enjoy their own personalized audio experience.

Fast Forward to Today

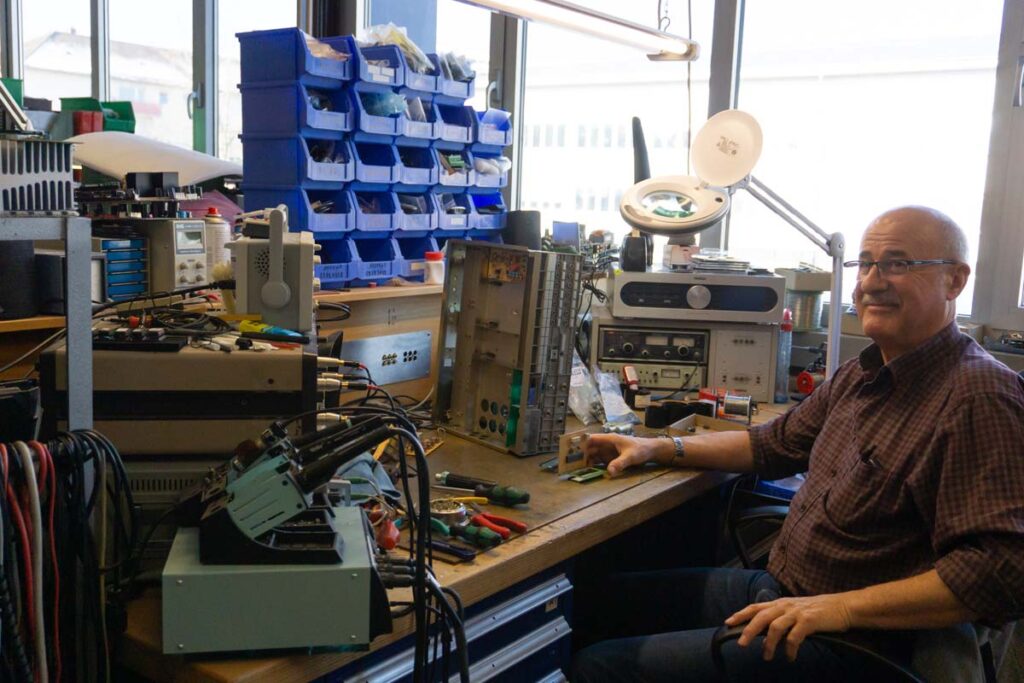

After our quick trip through the company’s history, Marketing Director Jürgen Imandt introduced us to a familiar name in the analog scene: Volker Lange from Horch House. Revox brought the tape specialists in-house to produce their own tapes in the best possible quality. To verify results, the team in Villingen uses a dedicated listening room with a modern, home-like atmosphere. That’s where we got our first impressions of the B77 MK III test model.

What really stood out? The innovative app integration and remote control functionality for this analog machine.

In-House Production

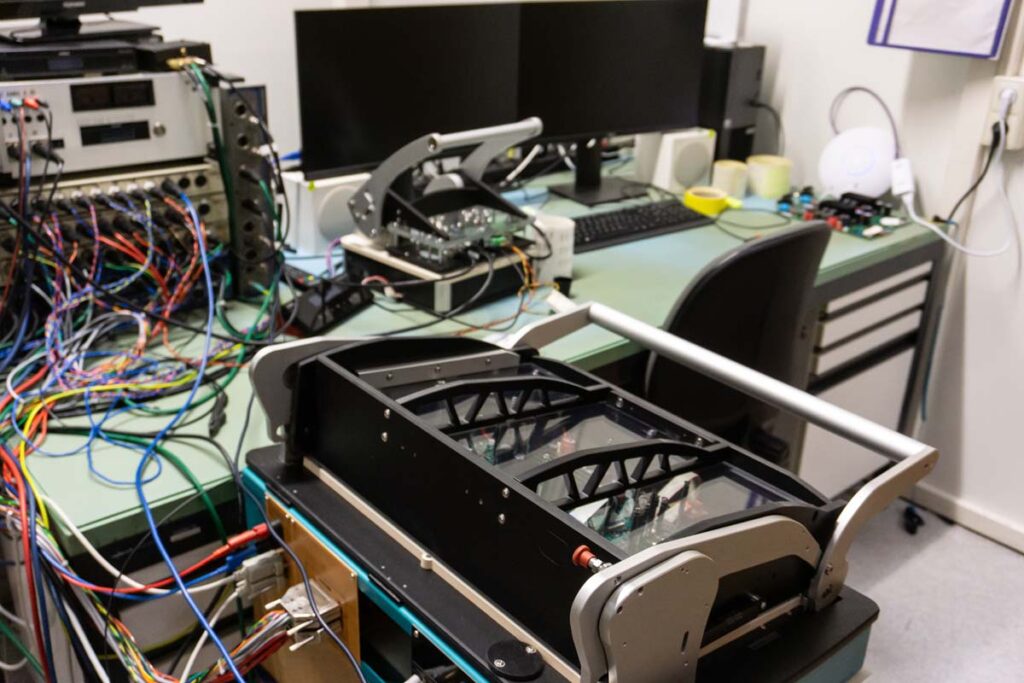

We then moved on to tape production. Any analog fan would be thrilled to see the arsenal of Studer A80 tape decks at work: these studio legends duplicate tapes in real time using raw stock from RTM. Each month, around 950 master tape copies are produced from Revox’s ever-growing music catalog. The tapes are packaged in climate-stable archival boxes – the same kind used in professional music archives.

Our tour then continued through the storage area and quality control department.

Every product is thoroughly tested before shipment. Right next to the warehouse is the production floor, which even has a dedicated burn-in department for circuit boards – a process that shortens the customer’s break-in time and ensures full performance from the very first minute. Along with turntables and loudspeakers (including invisible in-wall models), the B77 is also assembled here.

Because of Revox’s stringent quality standards, only 20 units per month can be handmade – there’s no sign of automation or assembly-line machinery.

Breathing New Life into Old Classics

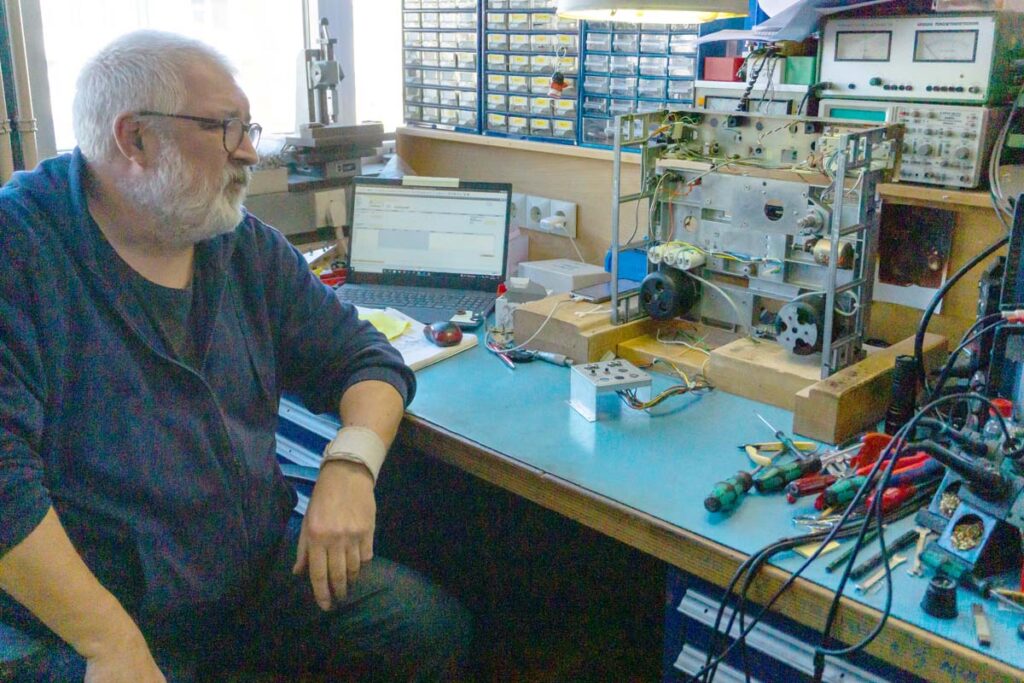

There’s a separate department at Revox for restoring vintage models – the “Classic” division. Here, older units are painstakingly refurbished and returned to their original delivery condition. That’s no coincidence: these machines were designed from the start for decades of reliable operation. Many owners send in their Revox units after 20 to 30 years for a full overhaul, since their sound and build quality are truly timeless.

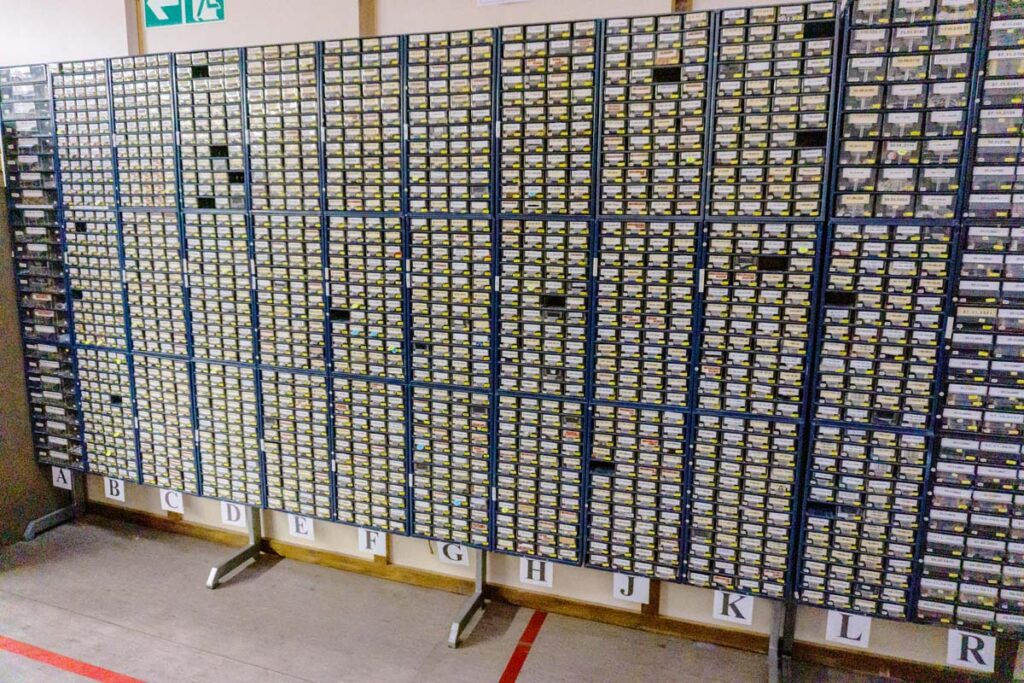

The team in Villingen actually has spare parts for every model ever produced – from buttons to motors to entire circuit boards. Each restored machine undergoes a rigorous inspection to ensure it not only works flawlessly but also looks exactly like it did when it left the factory. Revox is so confident in its restoration work that it offers a two-year warranty on the refurbished equipment.

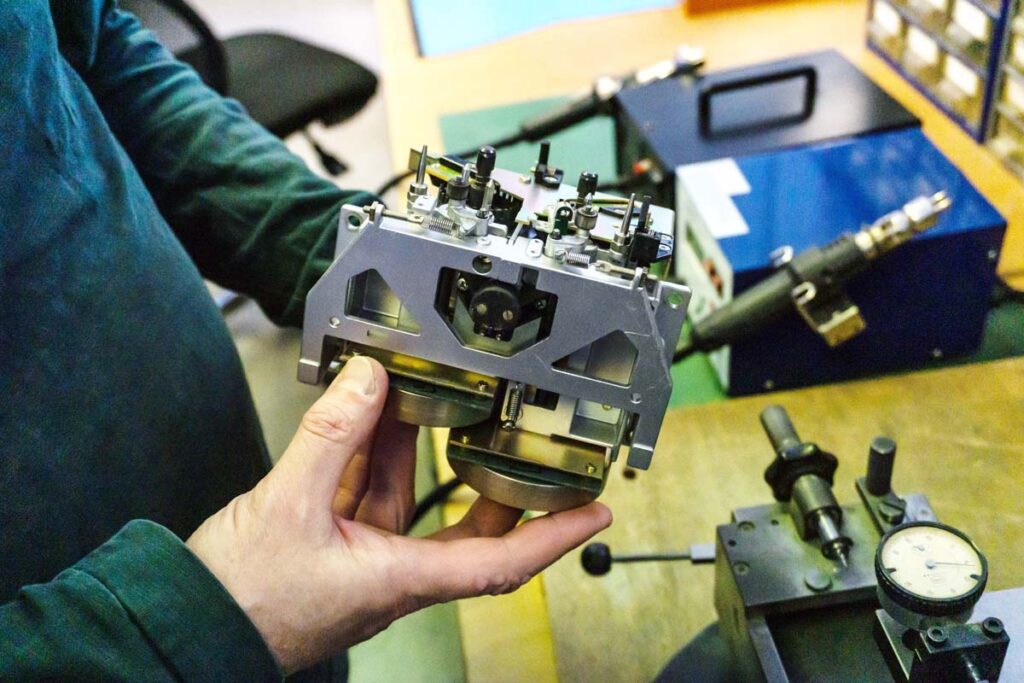

Parts, Parts, Parts

Revox in Villingen keeps every spare part needed to repair its vintage tape machines in stock. The only limits are technical expertise and meticulous attention to detail. In the photo below, you can see how extensively each unit is disassembled for repair, maintenance, or restoration. Due to the intense (and necessary) quality checks, there’s a long waiting list – but as the saying goes, good things take time.

Timeless Craftsmanship

The Classic service is currently in such high demand that wait times are at least a year. The Classic department feels like a workshop of memories – a place where the past and future coexist in a truly special way. There are very few companies that honor their history so actively and prove that a great piece of equipment never goes out of style.