Based in the Florence area, Gold Note is generally perceived as a young company. Yet the manufacturer is (mostly behind the scenes) one of the old hands in the business.

Picture the situation: On a high-fidelity press trip, not a single music track is played, we don’t see a listening room and the technical finesse of the devices also plays a subordinate role. Nevertheless, all the guests will later leave the building as moderately addicted fanboys. What does that tell us? First of all, that Gold Note gets a lot of things quite right, since a tour of the factory halls is all it takes to make you fall in love with the Italian machines …

Environmental Variables

Tuscany, birthplace of the Renaissance. We are barely 15 kilometers southwest of Florence in a landscape lined with rolling hills. Pine trees, spring sunshine and Italian delicacies wherever you look. It is not easy for German editors to focus on their work in such an environment. Maurizio Aterini finds it noticeably easier. For him, the dreamscape is part of everyday life. He sits in his office and works tirelessly on his computer, not particularly bothered by the small crowd of journalists outside, who are taking a tour of the building accompanied by his product manager Tommaso Dolfi.

Already A Tinkerer At Age Eight

Later, the CEO of Gold Note will tell us that he was already fascinated by tape machines and cassette decks as a young boy. He started repairing devices at the age of eight. He later studied engineering and soon developed his own components. From the early nineties, he worked as an OEM (original equipment manufacturer), one of those faceless producers who manufacture assemblies or entire devices for clients.

No Love For Financial Crises

In this role, his company flourished and manufactured for well-known European industry giants as well as a “North American market leader”. Of course, he is not at liberty to reveal any names – the contracts are still valid today. His customers wanted to preserve the aura of their own developments. At the end of the 2000s, however, the financial crisis also hit the lovely Tuscany region. Over the course of a few months, Aterini lost the majority of his customers. After the initial scare, he decided to take the plunge and founded his own brand, Gold Note.

Seasoned Veterans

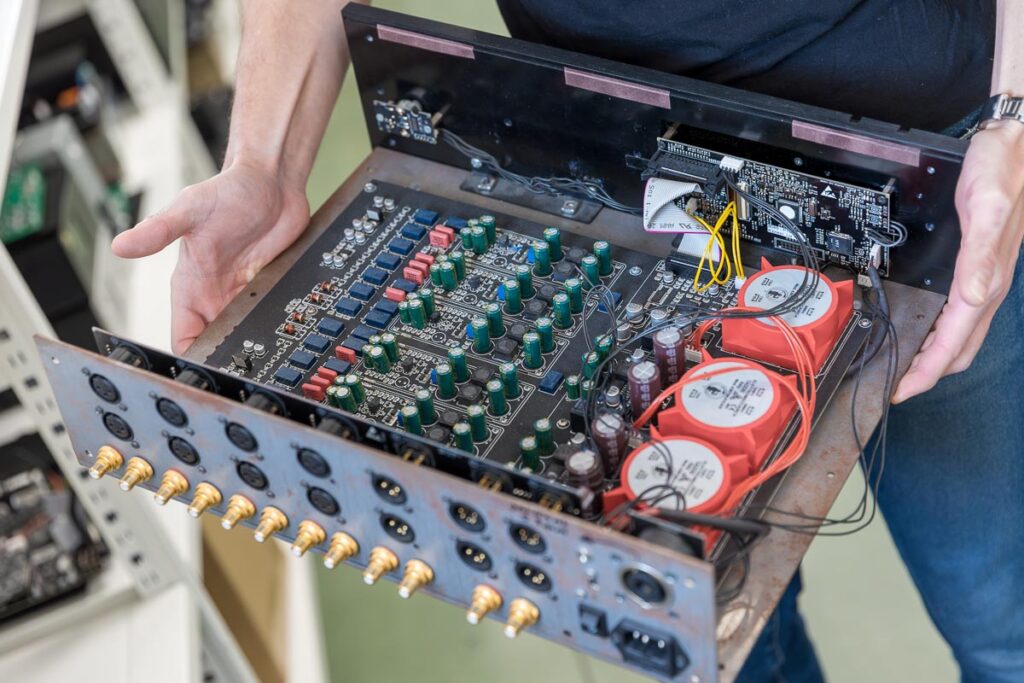

This brief outline of the managing director’s career answers a question that I have been asking myself for some time: How can a producer pop up overnight whose products are so sophisticated and show no teething troubles even when scrutinized meticulously? The Gold Note team’s almost 25 years of experience in all aspects of development and production when the company was founded (2011) was built into the components, yet not widely publicized.

Gold Note Pragmatism

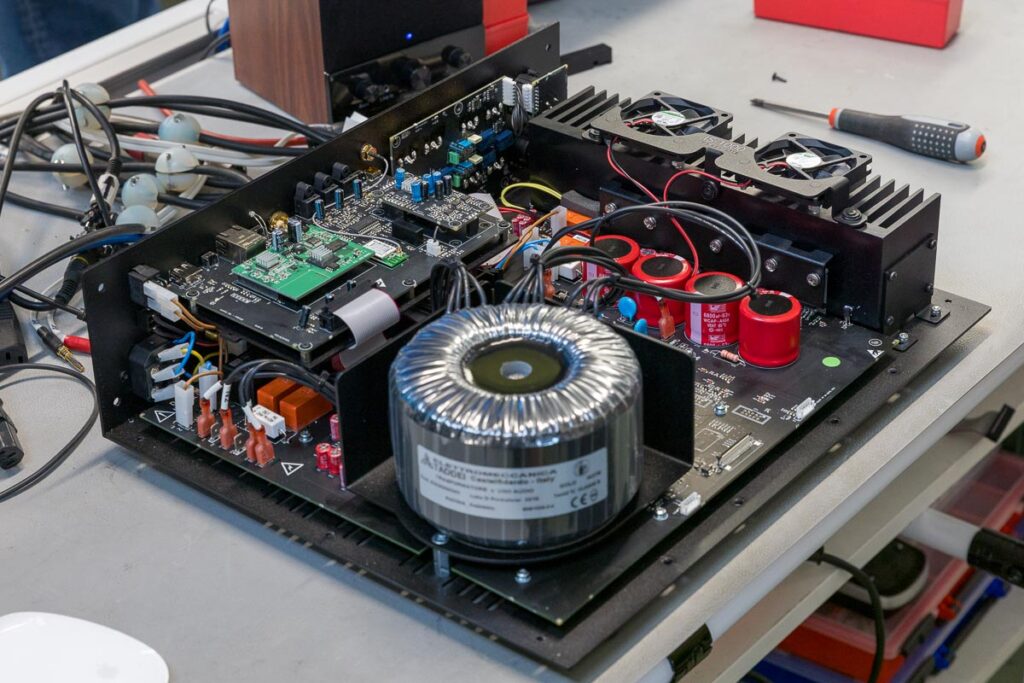

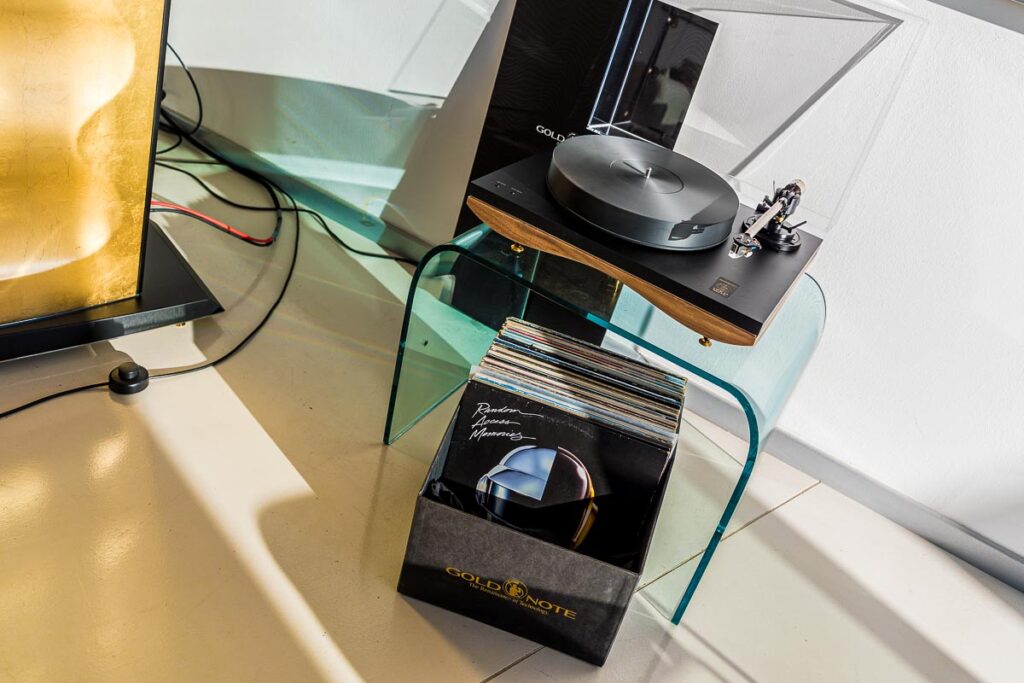

In other respects, too, the team are seasoned pragmatists. As already indicated in Aterini’s comments, the Italians place particular emphasis on clean circuitry, a solid construction of their power supplies and a no-frills, yet attractive design of their components. The focus is on technology, outstanding sound quality is quite simply the logical consequence. But please don’t misunderstand: Of course there are several listening rooms in the company building. However, they were occupied during our visit.

Price War Through Organization

Maurizio Aterini had one problem in particular in the early years of Gold Note: How can you produce top-class equipment with top-quality workmanship without letting prices get out of hand? The solution was found in an experienced optimizer who normally organizes processes for the automotive industry. His suggestions were not a mere tweak, but rather prompted the CEO to restructure his company from the ground up and even led to the company building in rural Montespertoli being remodeled. To ensure that processes ran as smoothly as possible, the offices and marketing department were moved to a separate wing of the building so that they were “no longer in the way” of production. We would come across the phrase “avoid unnecessary walking distances” a fair few times over the course of the tour.

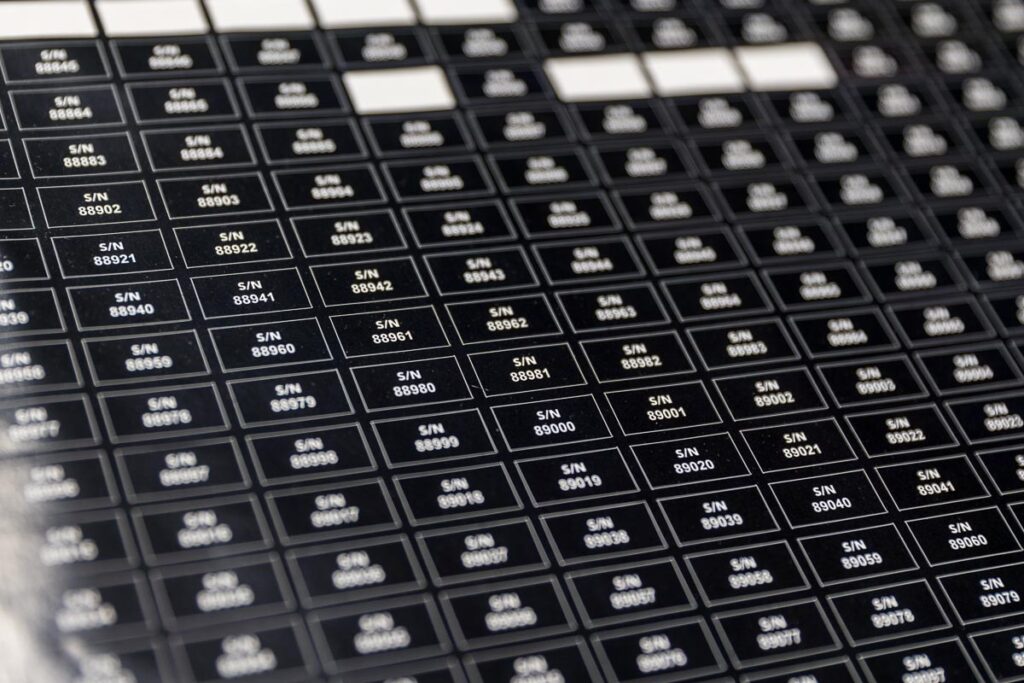

The Warehouse As Part Of Production

The starting point for Gold Note production is an elongated warehouse which, together with the shipping department, takes up almost the entire lower floor of the building complex. Two employees work tirelessly here, stocking self-designed rolling shelves with parts and components, housing blanks and other ingredients. Of course, they keep an eye on stock levels and immediately reorder any stock that is running low so that the process can continue tomorrow and the day after tomorrow without unnecessary breaks.

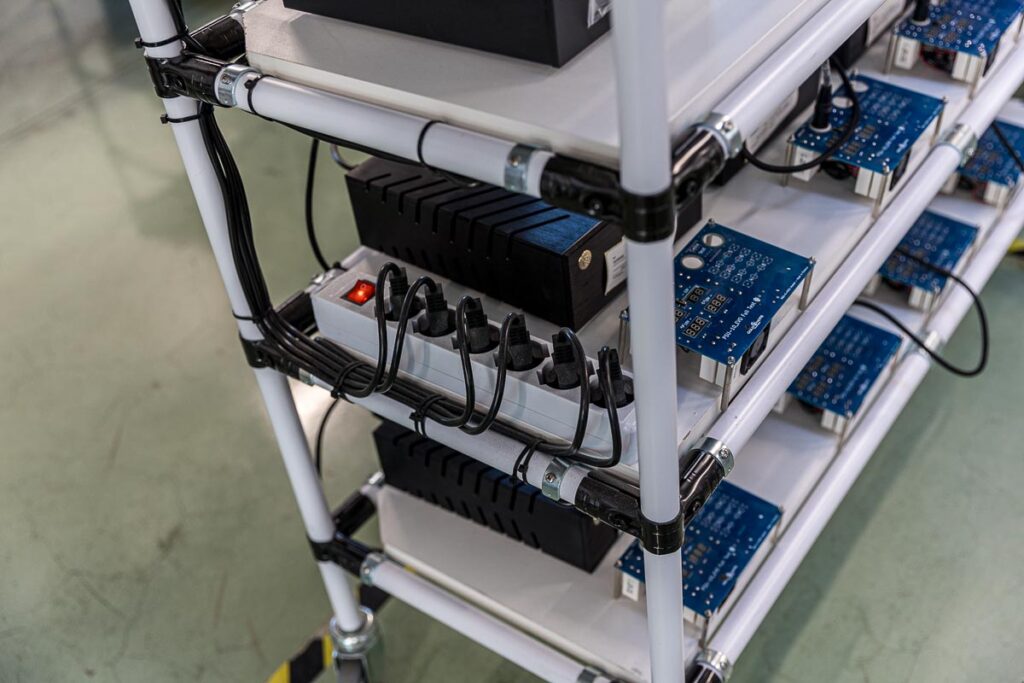

Just One Shelf Each …

“Each of the shelves is intended for one employee,” explains Product Manager Tommaso Dolfi, who shows us around the building. He or she will find it at their workplace the next morning. In the mobile mini-warehouses, all the parts are prepared for the production of a specific Gold Note component.

In the evenings, a board in the production area is used to meticulously record what has been completed and where there may have been a problem – where, for example, it was necessary to re-sort screws despite the sophisticated organization. “We don’t mean to build up pressure with this,” Dolfi is quick to point out. The restructuring is still in full swing and there is hidden potential in every nook and cranny. Part of the warehouse is currently being restructured. Some of the packaging was arranged here according to volume. Everything large and heavy was stored further down on the shelves. However, practice has quickly shown that these cardboard boxes are rarely needed. And in order to find such errors, active feedback from the employees carrying out the work is essential.

The Gold Note Formula Works!

This fine-tuning down to the smallest detail has led to a considerable increase in the output of devices with an identical workforce. And this in turn has an impact on component prices: The massive IS-1000 integrated streaming amplifier, for example, is priced at just under €4500. Considering that we’re talking about a powerhouse in the 18 kg-class complete with an excellent DAC and a good 250 watts per channel (4 ohms), this is a veritable bargain.

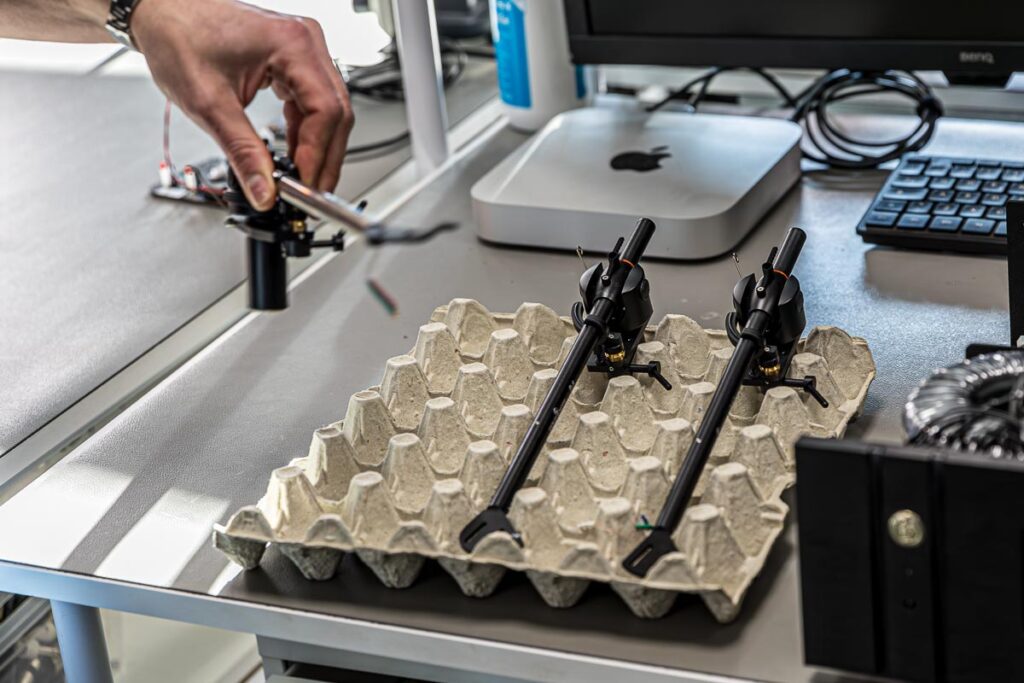

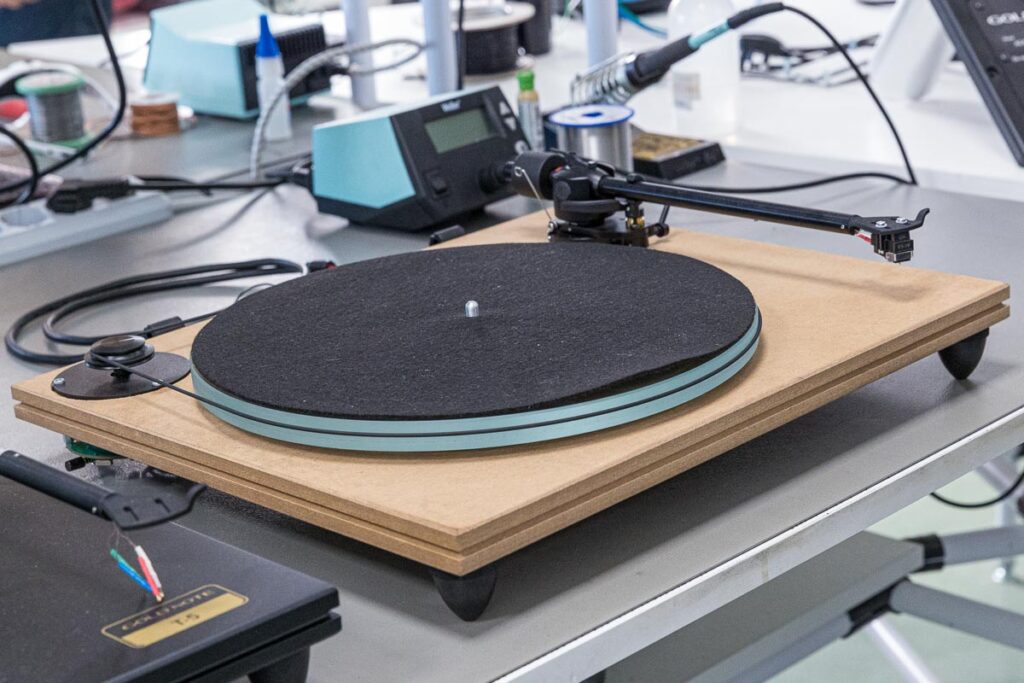

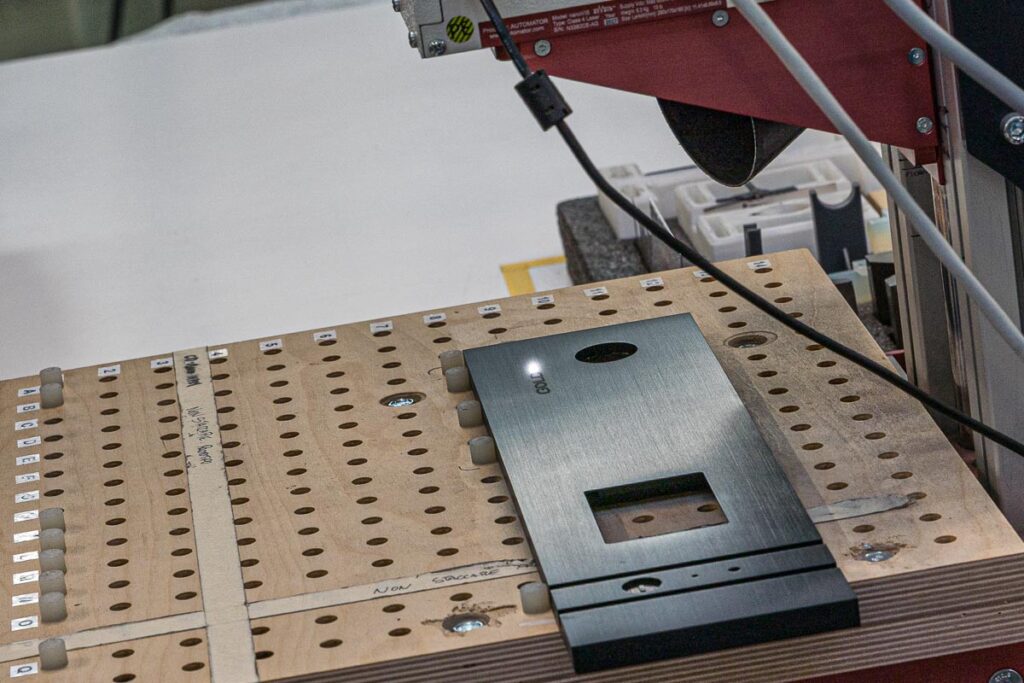

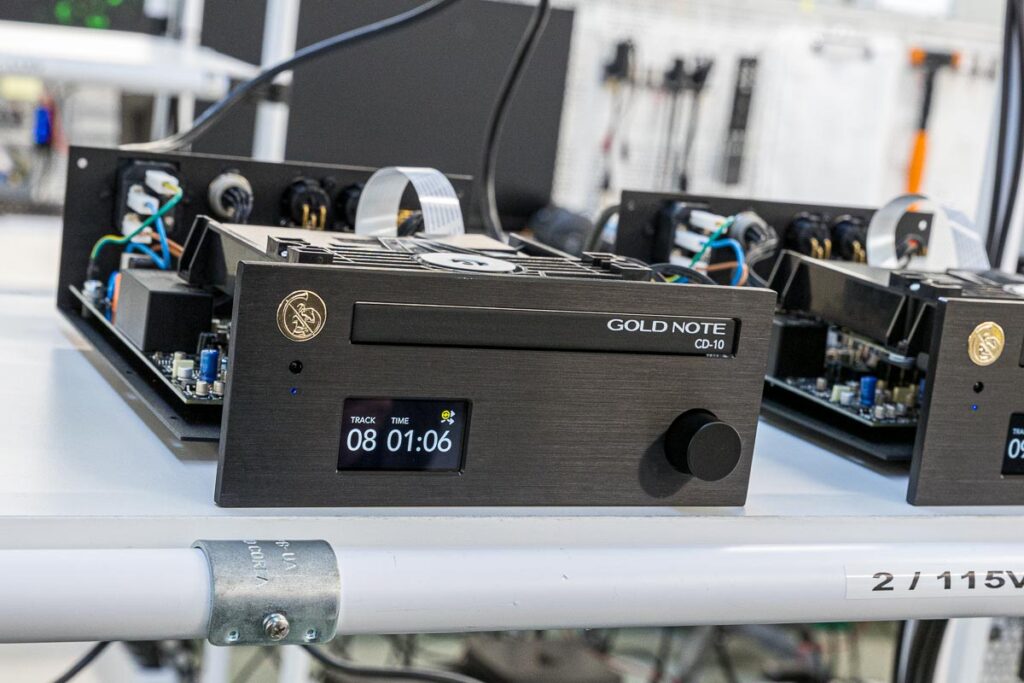

During our visit, around six employees are busy assembling all kinds of devices. I discover the compact IS-10 integrated streaming amplifier and its highly acclaimed IS-1000 brother. The slim T-5 turntable is being built at another workstation. Everything is done on clearly laid out workbenches, each equipped with its own measuring stations – and with another shelf where the fully assembled devices are burned in. This is also part of efficiency optimization: if a problem occurs, the employee responsible can put the defective unit straight back on the table and get to the bottom of the problem with measuring programs and all the necessary tools. Once the fault has been rectified, burn-in can continue.

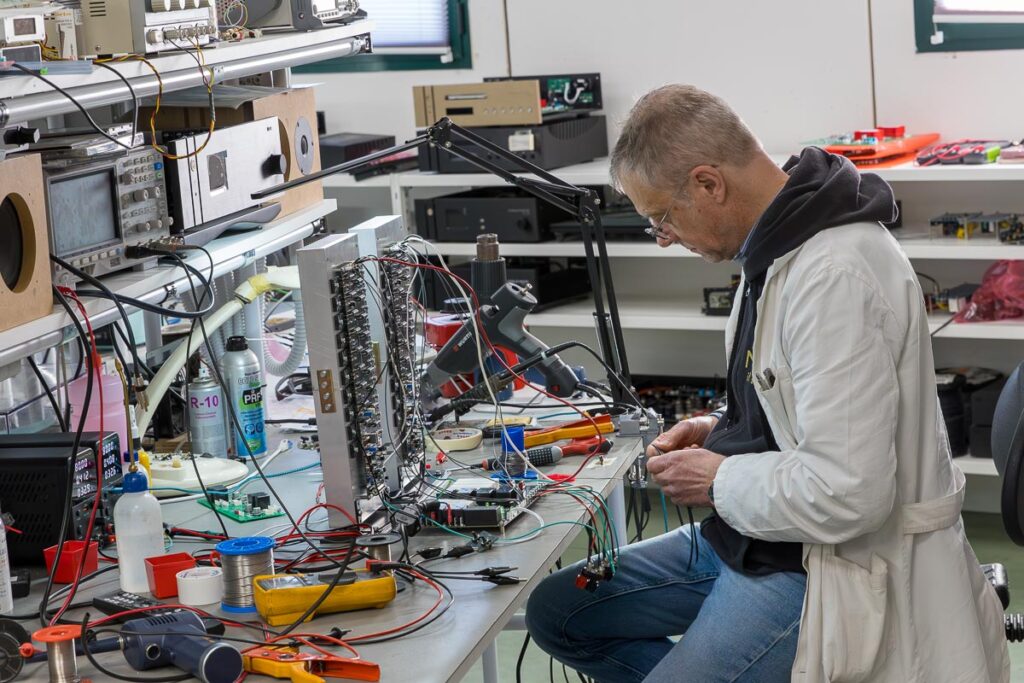

Service Included

Further back in the assembly hall, we discover the only workplace where a talent for improvisation is required: In the service area, machines from the early days of the brand are repaired. Of course, it is not possible to plan ahead for component requirements. However, the compact measuring station based on a meticulously calibrated standard sound card is also available here – and so the fault in the large power amplifier, which is currently waiting for the doctor, is sure to be analyzed and rectified soon.

Cool Packaging

This directness has also been transferred to the packing stations. Short routes, prepared materials and, above all, much better adapted cardboard packaging have virtually eliminated rejects and transport damage in recent years. Udo Besser from the German sales department demonstrated how the Mediterraneo record player is placed in its crate: There are suitable gaps in the packaging inserts for each part of the disassembled turntable. If a gap is left at the end, it means a part is missing – or vice versa. In comparison, most of the turntable cartons I know look like puzzles for advanced users.

So, Where’s Gold Note Headed?

During our final interview, I have the opportunity to ask Maurizio Aterini about the challenges ahead. Where does he see his company in five or ten years’ time? In addition to the goal of attractive prices, this was another reason for restructuring the company. In a nutshell: He doesn’t know! But if Gold Note works as efficiently and flexibly as it does at the moment, then it will be able to react quickly to new requirements. As my grandmother used to say: order is half the battle! And sometimes a little more …